Discover the benefits of bringing CCC’s best-in-class turbomachinery controls inside your Honeywell Experion PKS.

WATCH NOWDesigned to meet the requirements of multi-purpose dynamic simulators and operator training stations, the CCC Emulator is the simple tool for designing, tuning and testing turbomachinery control in simulation and directly transfer outcome to site control system. When you choose the CCC Emulator, our engineers become more integral members of your design team — conducting design review, fine-tuning and final simulation reviews to ensure your industrial project succeeds. If you’re searching for a versatile software application and expert engineering partner to minimize risk across the project lifecycle, you’ll find it in the CCC Emulator.

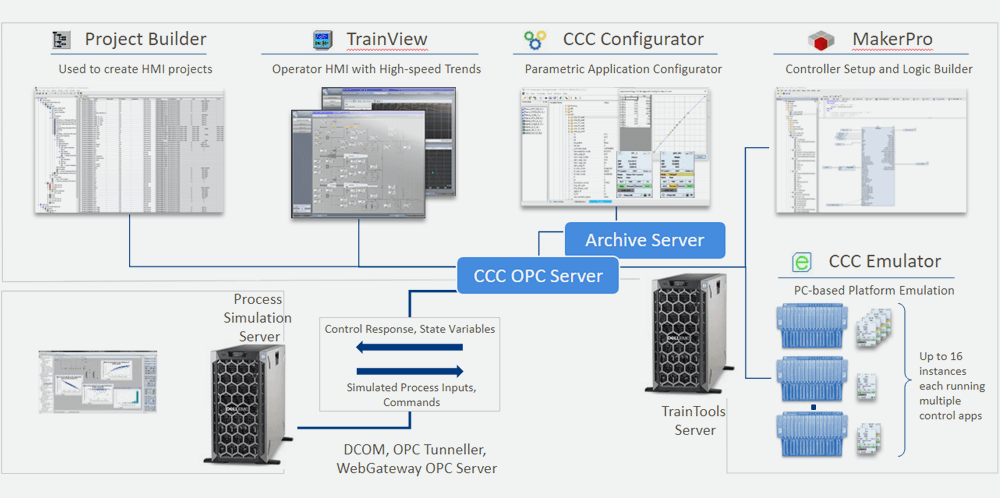

The CCC Emulator software application enables you to emulate a full plant CCC control system with a single tool. Operators can execute the entire suite of CCC control applications in a Windows OS environment that allows for interfacing with third-party process simulation software. Supporting both the S5 Emulator and Prodigy Emulator subprograms, the CCC Emulator seamlessly emulates up to 16 instances of CCC Pro Built controllers.

The S5 Emulator Supports

- S5 Vanguard

- S5 Reliant

- S5M real controllers

The S5 Prodigy Emulator Supports

- Prodigy

- S5P real controllers

- Any future CCC controller based on Codesys runtime

For operations leveraging Series 3 or Series 4 controllers, CCC can create an equivalent S5 or Prodigy configuration to emulate platforms including S3++ and S4.

Features and Benefits

From reducing startup time to enabling more seamless training, the CCC Emulator was designed for the unique challenges of industrial operations.

Key Capabilities

- Utilizes the same TrainTools engineering tools and TrainView HMI as the control system

- Converts and rebuilds the CCC control system program for an Emulator target rather than a real controller target

- Ensures an exact replica of control system logic and responses to enable automated conversion

- Easily transfers snapshot with configuration and tuning parameters from real controllers to the CCC Emulator and vice versa

- Supports as many as 16 instances corresponding to 16 real controllers

Proven Value

- Validates real control solutions in a dynamic mode

- Enables extensive tuning in extreme scenarios that cannot be tested in the field

- Equips teams to start commissioning from a model-based tuning rather than default parameters, reducing control system startup time

- Enables operator training with identical interfaces

- Reduces project risk and startup time

- Provides expertise from CCC engineers who have the specialized knowledge required to minimize risk and optimize design

Lifecycle Applications

Operating alongside third-party process simulation software, the CCC Emulator acts as a Multi-Purpose Dynamic Simulator (MPDS) for your turbomachinery controls system throughout the plant project lifecycle, from engineering studies through ongoing optimization. Its many lifestyle applications include:

- FEED: Engineering studies to correct system design

- EPC: Engineering studies for control strategy testing and validation

- Pre-Commissioning: Control system pre-tuning and Operator Training Simulators (OTS)

- Operation and Optimization: Digital twins for real-time model-based optimization and engineering studies with as-built configuration, “what if” scenarios or future design change validation

Engineering Studies

During engineering studies, the CCC Emulator can evaluate control dynamics during a wide range of scenarios including turndown operations, sequencing of the machine, fast-transient upsets, and normal operations based on design conditions and gas composition. Organizations can utilize this emulator data to assess and optimize critical aspects of their turbomachinery controls strategy, including:

- Overall control system design, configuration and tuning

- Steady-state and turndown operation with different gas compositions

- Protection from surge during fast disturbances, leveraging Recycle Trip, Safety On and Derivative Responses

- Verification of antisurge valve sizing

- Protection from over and under pressure with proper combined response of multiple limiting loops, pressure override control and set point depression

- Layered response coordinated with other DCS and SIS controls and protections

- Operating procedures and machinery sequencing including purging, pressurizing, startup, load, unload, normal stop and emergency shutdown

Compatibility With 3rd Party Process Simulation Software

The CCC Emulator can interface with leading third-party process simulation software via OPC.

Standard interfaces such as links or connectors have been developed by many industrial process simulation software vendors. Although CCC may have been involved in providing technical information, guidance and validation for their interface development, these interfaces are owned and maintained by each third party company.

The partial list provided in the table below is for informational purposes and may not be up-to-date. We recommend that you contact the vendor directly during the proposal phase to verify the current state of the interface with the Prodigy Emulator or S5 Emulator.

| Company | Software | S5 Emulator | Prodigy Emulator |

|---|---|---|---|

| AspenTech | HYSYS Dynamics | V2006.4, v7.1, v7.2, v7.3, v.8.6 and later | V11.0 or higher |

| Honeywell | Process Training Simulator (former UniSim Operations) | R400 and higher with CCC Toolkit & Adapter | R521 and higher with CCC Toolkit & Adapter |

| Omega Simulation | OmegaLand | Yes | Yes |

| Emerson | DeltaV Simulate | Yes | No |

| Emerson | Mimic Simulation | No | Yes |

| AVEVA | Dynamic Simulator (former Dynsim) | Yes | Being developed in Q2 2023 |

| Kongsberg | Asset | Yes | No |

| Kongsberg | K-spice | Yes | Yes |

| CORYS | INDISS | Yes | No |

| CORYS | INDISS PLUS | Yes | Yes |

| BHGE | Predix | Yes | Yes |

| Inprocess | Inprocess Infrastructure Suite | No | Being developed in Q2 2023 |