Enhance your turbomachinery performance and reliability by leveraging the power of digital and embedded expertise.

WATCH NOWUpgrade Your EAS (Emergency Anti-Surge) Detector Today For Optimized Compressor Protection

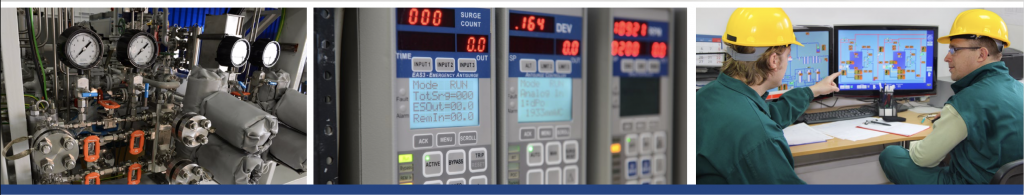

Upgrade Your Surge Detector with the NEW Smart CCC EAS3 to Prevent Damage to Your Compressor

Drop-in replacement of your CCC EAS for even more protection with upgraded features

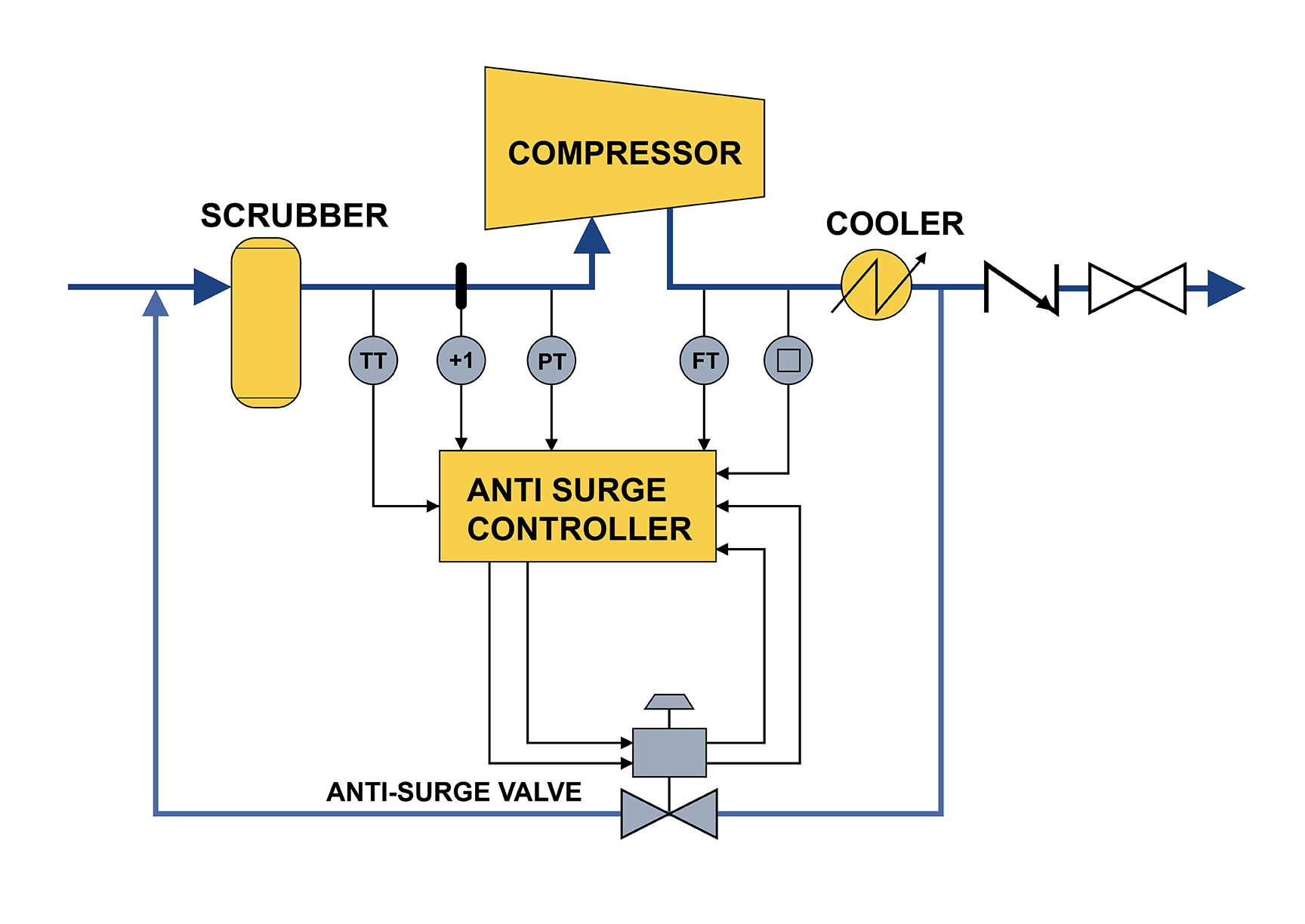

The CCC EAS3 anti-surge detector is for process plant operators, owners and rotating equipment engineers who need to prevent costly equipment damage caused by surging of their process gas compressors. The EAS is easily upgraded without changing the cabinet, wiring or documentation in your current installation. CCC prevents a significant amount of design, work, and downtime required from PLC (Programmable Logic Controllers) based systems as the cabinet does not need to be modified or replaced. You will have peace of mind for your compressor operation with CCC EAS3 surge detection, manual loading, drop-in replacement and diagnostics.

The CCC EAS3 Features…

- Monitoring, detection and counting of compressor surge events for diagnostics

- Protecting the compressor in the event of excess surge events in set time limits

- Control the compressor speed through manual loading station functionality

- Auto-loading compressor control

- A simple upgrade to the EAS3 with plug and replace technology

- All data and functionality is available to the DCS feed via Modbus or ethernet

Compressor protection for new installations

The EAS3 provides cost effective anti-surge protection of redundancy for the CCC 3++ controller and can be easily installed for new compressor units. Operators will immediately experience the benefits of the auto/manual loading station providing a cost-effective method of redundancy for the controller. The EAS3 opens the anti-surge valve to protect the compressor in the event that it surges multiple times in a pre-determined timeframe. This offers a high level of protection for expensive process gas compressors.

The auto and manual loading aspect of the EAS3 is unique to CCC. If you currently use inputs from a PLC (Parallel Logic Controller) into a safety system or surge protector with a manual control, you will be astounded at the simple and reliable EAS3 functionality.

The EAS3 is the replacement and migration product for the legacy Emergency Anti-surge Station (EAS). It provides the full functionality of the original EAS along with new features including diagnostics. It drops into the existing EAS footprint with ease. For process plant operators requiring a new unit, CCC includes the auto and manual loading station feature, providing a cost-effective method of redundancy for the controller.

Overview

The EAS3 is a versatile surge-detecting device that can be employed in a variety of compressor control applications.

For example, it can be employed as an auto/manual or manual loading station for your primary surge protection system. In the event that your anti-surge controller fails, the EAS3 will control your recycle valve while you install a replacement controller.

Unlike other auto/manual stations, the EAS3 can track the output of the controller providing smooth, bumpless transfer into and out of manual mode.

The EAS3 will detect any compressor surges that occur, and automatically take control of the recycle or blow-off valve if the primary anti-surge controller faults or fails to prevent repeated surging.

Another common use for the EAS3 is to provide a convenient method of manually controlling a recycle valve when the anti-surge controller is installed far from the compressor. Simply install the anti-surge controller in your control room and route the output through an EAS mounted near the valve. You can then temporarily assume manual control of the valve at the valve site, while still retaining automatic surge protection.

The EAS3 can also be used as a high-speed, external surge detector for an anti-surge strategy implemented in a Distributed Control System (DCS) or programmable controller. In such applications, it will provide a digital signal to the DCS each time a surge occurs and a series of discrete signals indicating the cumulative surge count.

By providing both surge detection and manual loading functions, the EAS3 takes the place of two devices, saving you money and control panel space while simplifying the control scheme.

Process, controls, safety, machinery engineers and plant executives optimize plant safety, capacity, efficiency and reliability every day utilizing CCC expertise. Our 45 plus years of experience brings a universe of machinery control solutions in various industries. We have the local resources and decades of turbomachinery systems knowledge to support your global asset optimization.

Anti-surge control devices are crucial protection to keep your assets operating effectively. Deploying or upgrading to the CCC EAS3 smart alarm system optimizes monitoring, enabling quick corrective action, effectively increasing output, avoiding unnecessary costs, and ultimately prolonging your turbomachinery lifecycle.

The CCC EAS3 is a smart solution providing benefits that you can not get from general-purpose programmable logic controllers or switches including:

- Detection and counting of compressor surge events

- Trip the compressor in the event of excess surge events within the set time limit

- Ability to manually control the speed of the compressor through the manual loading station functionality. Auto-loading functionality provides bumpless transfer of surge value control

- Fits into the same physical space as the old EAS – no modifications to the cabinet or wiring are necessary

- Increased compressor protection because it can independently detect surge and automatically take over when your antisurge controller fails

- More reliable surge detection due to high speed monitoring of two process variables

- Greater versatility because its many features can be configured to the needs of your application

- More options when interfacing to DCS or PLC control systems due to the variety of digital and analog inputs and outputs

Key Specifications – How the CCC EAS3 Works

- Opens the anti-surge valve to protect the centrifugal compressor in the event that it surges multiple times within the selected timeframe.

- Depending on your needs, the EAS3 can be configured as a Surge Detection Station (with or without analog output) or a backup anti-surge station (Auto/Manual or Manual Loading Station).

- By providing both surge detection and manual loading functions, the EAS3 will take the place of two devices, saving you money and control panel space.

- Operators gain reliable surge detection due to high speed monitoring of two process variables.

- The designated inputs (usually the flow rate and discharge pressure or motorpower) are monitored for high rates-of-change typical of a surge.

- The EAS3 maintains both an event and a cumulative surge counter.

- Four surge alarms (1A, 1B, 2A, and 2B) are provided, each with a dedicated discrete output. Process and rotating equipment engineers specify how many event surges must be detected before each is triggered.

- The operator achieves increased compressor protection as EAS3 independently detects surge and automatically takes over when your anti-surge controller fails.

In order to satisfy this wide variety of applications, the EAS3 can be set up in any of three basic station configurations:

- A Surge Detection Station (SDS) can use either or both of its analog inputs to monitor your compressor for the flow or pressure drops (or fluctuations of any other appropriate process variable) that characterize an actual surge. It provides a variety of analog and discrete outputs that can be used to control external alarms, to communicate the number of surges to an external control system, or even to implement an open-loop anti-surge control loop.

- An Auto/Manual Station (AMS) uses one analog input to monitor your compressor for surge and another to track the output of a primary antisurge controller. If the primary controller faults or fails to protect the compressor from surge, the AMS will automatically and bumplessly take control of the anti-surge valve.

- A Manual Loading Station (MLS) is a non-tracking version of the AMS that usually uses both of its analog inputs to monitor your compressor for surge. Because it does not track the output of the primary controller, it cannot provide a bumpless transfer when it takes or returns control of the antisurge valve.

Compressor surge entails rapid drops in both flow rate and head, followed by a rapid increase in flow and somewhat less rapid increase in head. Conversely, the suction pressure usually spikes, and then declines. Numerous related variables exhibit similarly rapid variations. Thus, it is possible to infer the occurrence of a surge from a tellingly rapid change in a variety of process measurements.

Depending on which basic configuration you select, the EAS will monitor either or both of its analog input signals (CH1 and CH2) for these characteristically rapid fluctuations (in the Auto/Manual Station configuration, only CH1 is available):

- It can be set up to monitor only CH1 or only CH2, incrementing its surge counters when the selected input’s rate-of-change (in either direction) exceeds a user-defined threshold.

- It can be set up to monitor both inputs and to increment its surge counters when either’s rate-of-change exceeds the correspond- ing threshold.

- It can be set up to increment its surge counters only when both inputs’ rates-of-change exceed the corresponding thresholds within a user-defined period of time, in any order.

Surge Alarms and Responses

Each time it detects a surge, the EAS3 increments two counters, each of which can be displayed by the front-panel digital readouts:

- The event surge count, which is reset to zero when the surge alarms are manually or automatically reset, is the number of surge cycles detected during the most recent surge event.

- The interpretation of the accumulated surge count, which does not change when the surge alarms are reset but can be given any desired value at any time, depends on when and to what value it was last set. For example, if this count was set to zero when the EAS3 was installed and has not been manually altered since, its value will be the total number of times the compressor has surged since the EAS3 was installed.

The station can also accept a surge discrete input signal from an external surge detector and transmit a discrete output pulse each time it detects a surge.

Four alarms (1A to 2B) are triggered as the event surge count rises past user-specified levels. As each alarm is tripped, the corresponding front-panel LED will either begin flashing (for a level A alarm) or light continuously (for a level B alarm) and the corresponding discrete output is energized. Each alarm can also raise the intended valve flow (from which the analog output is calculated) to a specified level or by a specified amount.

The alarms can be reset from the Front Panel or by asserting a discrete input. They can also be configured to reset automatically if a user-defined period of time elapses without a surge, as long as the event surge count is less than a user-defined latch value.

In any case, resetting the alarms sets the event surge count back to zero, turns both ALARM LEDs off, and clears the Alarm discrete outputs. However, the intended valve flow must be separately reset, generally by pressing the RETURN ANALOG key.

Auto/Manual Station

When configured as an Auto/Manual Station (AMS) for your antisurge controller, the EAS functions as a tracking backup station with integral surge detection and protection features. One analog input is used to monitor the compressor for signs that a surge has occurred, the other is used to track the output of the primary controller.

An internal relay connects the output of either the primary controller or the EAS3 to the recycle valve. When the AMS is in its tracking mode, this relay is de-energized. This passes the output of the primary anti-surge controller directly through to the control valve.

Pressing the TAKE CONTROL key causes the AMS to energize this relay, thus sending its own output to the valve instead. Depending on how it is configured, the AMS will then enter either its run or manual-only operating mode. The run mode offers the same manual and automatic features as the Surge Detection Station, while the manual-only mode gives the operator exclusive control of the output signal. In either case, the initial value of the EAS3 output will be calculated by adding offset to the output of the primary controller.

The AMS can also be switched to the run mode by asserting the TAKE CONTROL discrete input, and can automatically switch to the run mode if it detects more than a user-defined number of surges (presumably indicating that the primary controller has been unable to stop them). It will also take over automatically when the primary controller faults.

You can return control of the recycle valve to the primary controller by pressing the RETURN ANALOG key, or by asserting the corresponding discrete input. The AMS will then ramp the value of its output toward that of the primary controller until the difference is less than a user-defined deadband, at which point the output selection relay will de-energize.

Manual Loading Station

When set up as a Manual Loading Station (MLS) for your antisurge controller, the EAS3 functions as a non- tracking backup to your primary antisurge controller. This configuration is much like the Auto/Manual Station, except that it does not use its second analog input to track the output of the primary anti-surge controller. This frees that input for use in detecting surge. Consequently, the MLS offers the same surge detection options as the Surge Detection Station.

The MLS can be switched to the run or manual mode using the same methods as its tracking counterpart. In this case, however, the output will initially be set according to any previously tripped alarms (because it doesn’t track the primary controller, the MLS can’t start from that controller’s current output).

The same methods are also used for returning control of the antisurge valve to the primary controller. In this case, the transfer occurs immediately (because it doesn’t track the primary controller, the MLS cannot effect a bumpless transfer).