Enhance your turbomachinery performance and reliability by leveraging the power of digital and embedded expertise.

WATCH NOWA Part of Honeywell Asset Performance Portfolio | Enhance Turbomachinery Performance and Reliability by Leveraging the Power of Digital and Embedded Expertise

Turbomachinery Advisor is an advanced module in Honeywell’s Asset Performance Management (APM) for industrials portfolio. The module can be deployed on premises or in the cloud via Honeywell Forge. Turbomachinery Advisor helps customers get the most out of CCC turbomachinery control systems with:

- CRITICAL EVENT ANALYSIS

Support quicker and more thorough event investigations - EXCESS RECYCLE MONITORING

Detect and estimate excess energy usage and associated emissions - PERFORMANCE CONTROLLER MONITORING

Identify and address underperforming control loops

Solving Compressor Reliability and Performance Challenges Through Digitalization

Unlock new opportunities to advance and unify asset performance practices with advanced digital technologies. Download our white paper today to gain expert insights and strategies.

Benefits

Turbomachinery Advisor enables end users to continuously monitor CCC turbomachinery control systems for further optimization opportunities in:

Increased Uptime | Reduced Energy Consumption | Increased Production

Explore Features

Standard Model Library

Out-of-the-box asset models enable faster deployment and personnel to focus on optimizing operations.

Guided Root Cause Analysis

Helps shorten response time and identify the root cause of an event.

Cross-Functional Collaboration

Includes persona-based displays and enterprise-level KPIs.

Dig Deeper into New Modules

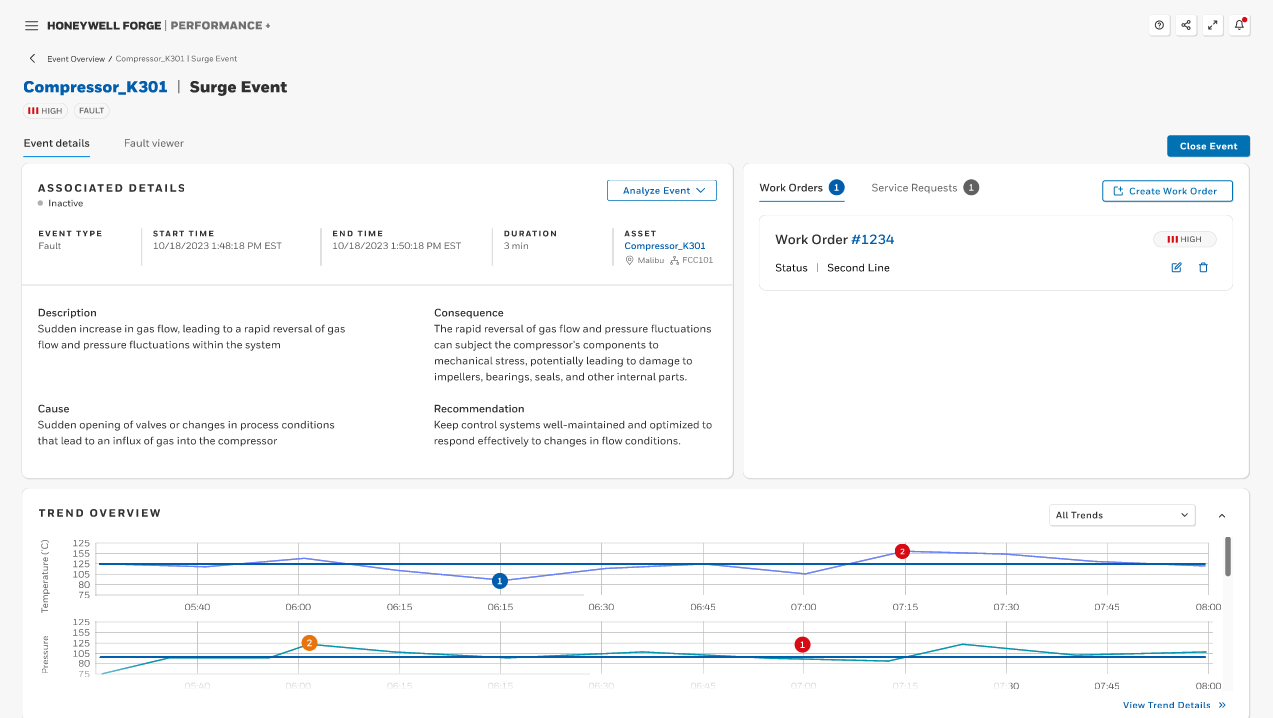

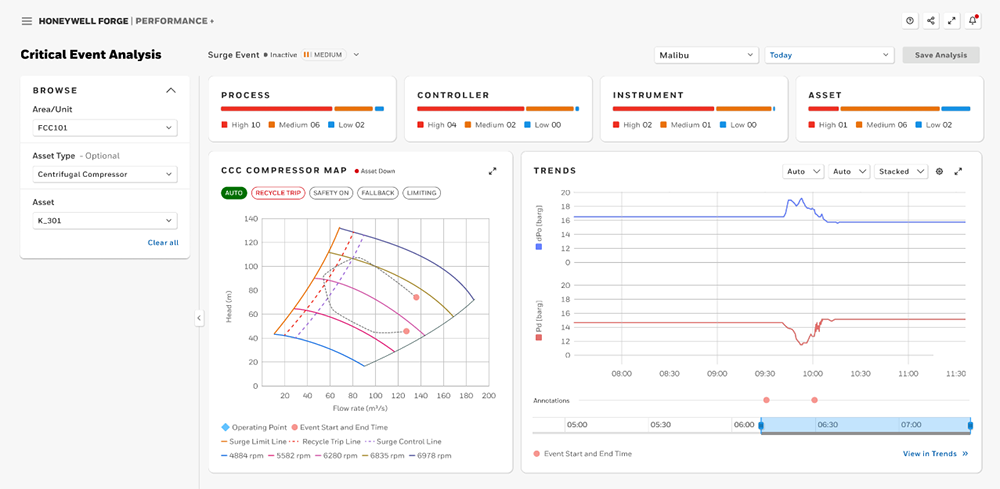

CRITICAL EVENT ANALYSIS

Instrument & Controls (I&C) Engineers and Rotating Equipment Engineers can:

- Analyze critical events, including compressor surge and emergency shutdown scenarios using high-resolution data and dynamic compressor maps.

Key Benefit

- Timely and More Accurate Corrective Actions

Quick access to high-quality time-series data can lead to faster restarts and prevention of secondary damages.

Important Features

The Critical Event Analysis module facilitates faster and safer process restarts by streamlining post-event analysis and provides these features:

- Milliseconds On-Event Data

Get access to native high-resolution data from TrainTools servers within minutes of critical events occurring. - Summary Score Cards

Pre-configured analysis highlights critical control loop element performance during an event for initial insights. - Dynamic Compressor Map

Displays compressor surge limit line and control lines in a dynamic form with support for data playback.

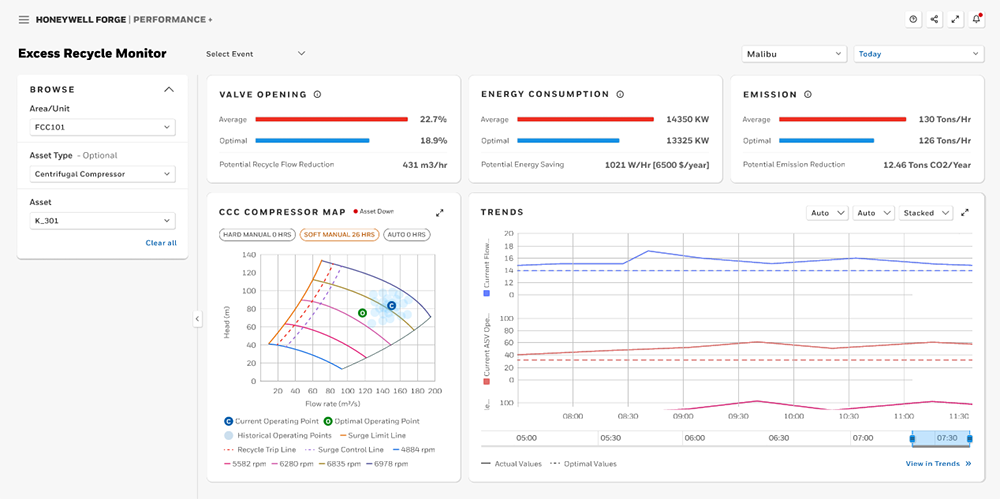

EXCESS RECYCLE MONITOR

Operations Supervisors and Instrument & Controls (I&C) Engineers can:

- Identify and quantify energy wastes associated with manual operation of antisurge valves.

- Calculate optimal valve opening under automatic mode to reduce energy consumption and emissions.

Key Benefits

- Energy and Cost Savings

Automatic detection of excess recycle conditions to prevent unnecessary energy consumption and associated costs. - Environmental Impact Assessment

Estimation of excess emissions and reduction of carbon footprint through optimized antisurge valve operation. - Process Stability and Equipment Protection

Prevention of delayed control responses, unstable processes and reduced effectiveness in equipment protection.

Important Features

The Excess Recycle Monitoring module identifies and quantifies energy losses and associated emissions from excess recycle and provides these features:

- Reliable Assessment

Automatic analysis flags excess recycle where flow through compressor is greater than process demand due to antisurge valve placed in manual mode. - Intuitive Visualizations

Transparent calculations with compressor map visualization boost confidence in data and recommended actions.

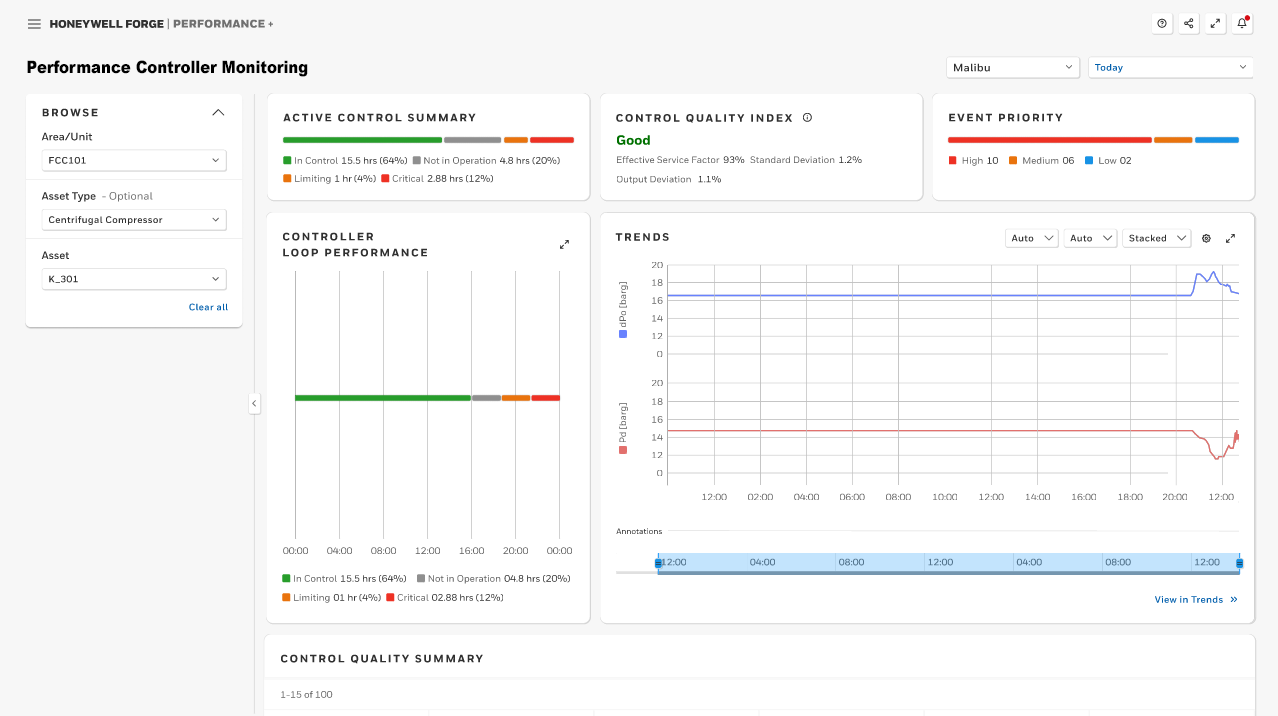

PERFORMANCE CONTROLLER MONITORING

Instrument & Controls (I&C) Engineers and Process (Controls) Engineers can:

- Identify and optimize control loops that are underperforming relative to expectations.

- Improve operational KPIs by understanding and enhancing the efficiency of primary and secondary control loops.

Key Benefit

- Production Improvement

Monitoring and reviewing how control loops are performing over time can lead to insights and optimization opportunities that improve production.

Important Features

The Control Performance Module identifies control loops that are underperforming due to various constraints, recommends corrective actions and provides these features:

- Automated Flagging

The model automatically flags control loops that are frequently constrained due to secondary control objectives such as limiting loops. - Intuitive Visualizations

Summary of time spent in each of the control objectives (primary vs. secondary) as well as its associated control quality are displayed.

Helps industrial operators get the most out of their CCC turbomachinery control systems and mission critical assets like compressors by leveraging self-guided tools and diagnostics designed with over 5 decades of CCC turbomachinery controls know-how. It achieves this by enabling quicker and more through critical post event analysis, recommendation of the optimal operating condition to reduce excess recycle and energy use, and identification of unperforming control performance loops.

Turbomachinery Advisor is a collection of advanced, pre-built asset models and dashboards available in Honeywell’s asset performance management (APM) platforms. Turbomachinery Advisor can be deployed in cloud as a SaaS offering powered by Honeywell Forge Performance + For Industrials Asset Performance platform or be deployed on- premise with Honeywell Asset Performance Management platform.

Turbomachinery Advisor is one of over 40 pre-built industrial asset models available in Honeywell APM platforms. While the Honeywell APM platform is vendor agnostics, Turbomachinery Advisor is built for CCC control systems.

Turbomachinery Advisor helps solve challenges that are often unaddressed or manually done in asset performance management practices by going beyond common equipment modeling monitoring.

First, the solution improves the response time and quality of post-critical event analysis by seamlessly combining high resolution event data (100+ millisecond) with machinery data and accelerating root-cause analysis with powerful visualization tools, self-guided diagnostics tools, and pre-annotated compressor maps highlighting key moments reducing the time and missed insights from traditional analysis methods.

Second, Turbomachinery Advisor automates the monitoring of excess recycle flow through anti-surge valves. The tool will provide real-time visibility by flagging compressors operating in excess recycle, calculating equivalent excess emissions, identify savings opportunities, and provide recommendations for more efficient operation.

Additionally, Turbomachinery Advisor adds performance control monitoring providing engineers with new measures for control quality, trend visualization and analysis, and recommended corrective actions to improve compressor performance.

Our differentiators are:

- Embeds CCC IP

- Uniquely incorporates high-resolution event data and performance controller monitoring

- Pre-packages models and visualizations

- Solution is delivered as a service and scalable across an enterprise

Turbomachinery Advisor extends beyond the core capabilities of health and performance monitoring. These capabilities include critical event analysis, excess recycle monitoring, and performance controller monitoring. By incorporating high resolution process and machinery data and control analytics, reliability and maintenance engineers can have more comprehensive insights of how control performance and critical events impact the health and performance of individual compressors and complex trains. These insights can help engineers take additional actions to improve reliability and performance of compressors such as:

- Implement control strategies and maximize compressor performance to sustain optimal performance and meet primary control objectives

- Detect control, mechanical, or process issues before they result in unplanned downtime or machinery damage

- Perform faster and more in-depth event investigations with high resolution process data combined with machinery data

- Safely operate closer to the surge limit line while reducing energy use and emissions

Data from CCC controllers are continuously archived at 100+ milliseconds on CCC’s existing TrainTools HMI servers. The OPC Data Logger installed on the Train Tools server (newer than TTCR version 15.3) collects low- resolution data continuously and creates data files. High-resolution data files are generated by a patched version of Archive Exporter installed on the TrainTools Server. The high-resolution data files are exported only when a critical event occurs such as a surge or emergency shutdown. Both high- resolution and low-resolution data files are pushed to Honeywell APM platforms via file transfer protocols such as SFTP and SMB. The data files once received by the Honeywell APM platforms are parsed into Honeywell APM’s historian.

Yes. But it requires architecture and scope review by a solution consultant.

Critical Event Analysis offers similar benefits for CCC Connect for PI System by leveraging adaptive resolution data transfer. The Critical Event Analysis submodule in Turbomachinery Advisor takes the benefits even further by providing a web-based tool with pre-configured compressor maps, trend charts, event playback features, pre-populated expert annotations and analysis, comment logging and annotation tools that improves the collaboration for analyzing, historicizing, and reporting events.

In addition to the Critical Event Analysis submodule, Turbomachinery Advisor also includes additional capabilities of performance controller monitoring, and excess recycle monitoring in a single platform.

Yes, Turbomachinery Advisor is just one of many asset models available in Honeywell APM solutions. Honeywell APM solutions has a pre-built asset model library for over 40+ asset types. asset types include instruments, electrical assets, process units, static assets, rotating assets, and mobile assets for a variety of industries. These asset models are updated based on Honeywell expertise, industry standards, and the latest AI/ML modeling technologies. These available out-of-the-box models reduce asset configuration time and enables repeatable results that are scalable across the enterprise.